Blog Page

The Definitive Guide to Resins & Coatings in East Africa: Strategic Selection for Industrial Applications (2025 Edition)

Resin Selection in East Africa: A Complete Guide for Industry Leaders

1. Introduction: Why Resin Selection Matters in East Africa

In industries like construction, textiles, packaging, and leather finishing, the choice of resins and coatings is not simply a technical decision—it’s a strategic one. In East Africa, where markets are expanding rapidly but climate and regulatory demands are intense, resin selection can determine whether a business thrives or struggles.

Since 1982, Synresins, East and Central Africa’s largest resin manufacturer, has been developing high-performance materials tailored to these unique conditions. This guide brings clarity for decision-makers seeking durable, sustainable, and cost-effective solutions.

2. East African Market Landscape

Economic Growth and Sectoral Drivers

East Africa is urbanizing at record speed. Large-scale infrastructure projects and a growing middle class are driving demand for construction, housing, and consumer goods.

- Housing: Kenya faces a backlog of nearly 2 million housing units. This alone is fueling demand for paints, varnishes, adhesives, and protective coatings.

- Furniture: Valued at $496 million, Kenya’s furniture sector is the largest in East Africa, growing at 10% annually. This accelerates demand for wood coatings.

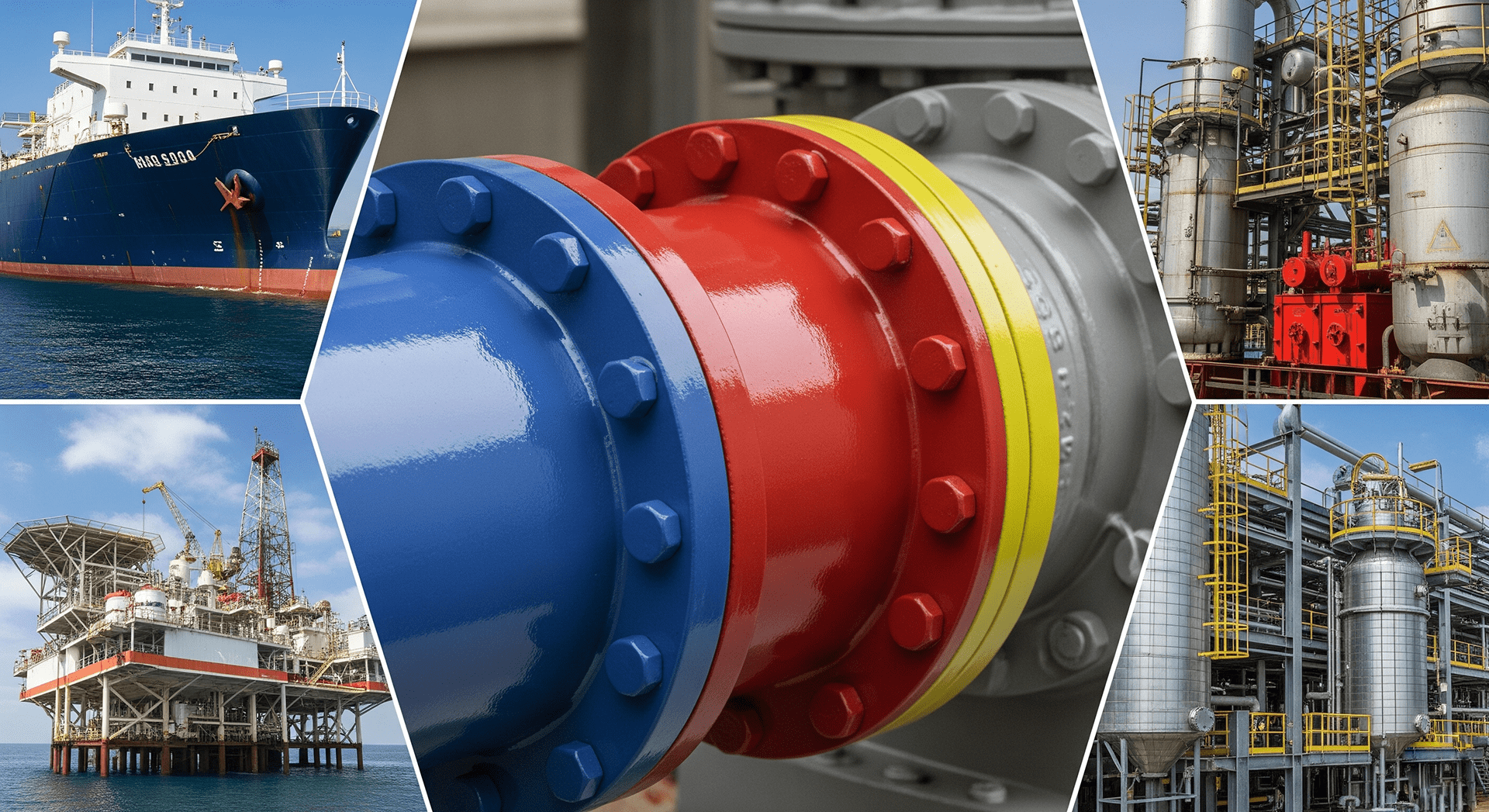

- Infrastructure: Road networks, industrial facilities, and vehicles all require high-performance coatings for durability and safety.

Why Global Brands Struggle and Local Leaders Thrive

While local demand is growing, international players like PPG and Kansai have divested from African markets, citing “sluggish” sales. The truth is, their standardized, high-cost solutions don’t align with the price-sensitive, logistics-challenged reality of the region.

This leaves room for agile, locally rooted leaders. With lean manufacturing, in-house R&D, and a Nairobi-based presence, Synresins is strategically positioned to deliver customized, cost-effective, and durable solutions.

3. The Regulatory & Sustainability Imperative

The East African Community (EAC) is adopting strict low-VOC standards for paints and varnishes. Globally, industries are transitioning away from solvent-based systems toward waterborne, powder, and bio-based resins.

This isn’t just about compliance—it’s about competitiveness. For instance:

- Kenya’s textile industry contributes 56% of industrial pollution. Regulators and consumers are demanding cleaner alternatives.

- Businesses that adopt eco-friendly solutions early are more likely to win contracts and international partnerships.

Synresins leads this transition with 100% green emulsions and eco-friendly products, helping businesses not only meet compliance but enhance their brand reputation.

4. Climate Challenges and Technical Demands

East Africa’s tropical climate—marked by UV radiation, heat, and humidity—is unforgiving to coatings:

- Heat & Expansion: High surface temperatures cause paint films to blister and peel.

- Humidity: Poor curing and surfactant leaching cause blotching and staining.

- UV Radiation: Accelerates fading, chalking, and cracking.

Every resin must be selected not just for cost, but as a shield against these stresses. This is why Synresins focuses on flexibility, UV stability, and moisture resistance in every formulation.

5. Technical Compendium of Resin Types

Alkyds: The Industry Workhorse

- Short-Oil (30–40%): Quick drying, ideal for metal coatings (e.g., automotive parts).

- Medium-Oil (45–55%): Widely used for enamels and architectural paints.

- Long-Oil (55–70%+): Excellent weathering resistance for exteriors and marine use.

Example: A coastal construction company in Mombasa can reduce repainting costs by 40% using long-oil alkyds for marine surfaces.

Polyesters: High-Performance for Composites

Used in fiberglass boats, GRP roofing, and auto body fillers, polyesters resist water, chemicals, and weathering. Synresins’ lab support helps clients manage challenges like odor and safe handling.

Homopolymers: Adhesives & Textiles

PVA-based homopolymers are used for wood glues, textiles, and adhesives. Water-based, fast-setting, and eco-friendly, they align with regulatory demands for low-VOC solutions.

Emulsions: The Sustainable Future

- Low/zero VOCs

- High flexibility

- Excellent UV resistance

Example: A Nairobi paint manufacturer switched to Synresins emulsions and extended product durability by 3 years—reducing warranty claims by 25%.

6. Strategic Resin Selection by Industry

| Industry | Challenge | Recommended Resin | Why it Works |

|---|---|---|---|

| Exterior Paints | UV fading, humidity | Acrylic Emulsions | Superior UV stability & flexibility |

| Industrial Coatings | Abrasion & chemical resistance | Short-Oil Alkyds, Hydroxylated Acrylics | Fast-drying, hard protective films |

| Road Markings | Durability & weathering | Alkyds | Proven resistance to traffic & weather |

| Leather | Sustainability | Water-based Acrylic Resins | Softer finishes & eco-compliance |

| Textiles | Pollution & recyclability | Homopolymers & Emulsions | Eco-friendly, strong binders |

| Packaging | Heat & humidity | Homopolymer Adhesives, Polyesters | Protects goods in tropical supply chains |

7. Synresins’ Commitment: Beyond Manufacturing

Synresins is more than a supplier:

- Founded in 1982, now East Africa’s largest resin manufacturer (10,000 MT annual capacity).

- Operates with Kaizen & Lean principles ensuring “100% Quality Right First Time.”

- Offers tailor-made solutions through advanced labs and a consultative approach.

This makes Synresins a strategic partner, not just a vendor.

8. Conclusion: Building a Durable Future

In East Africa, resin selection is about more than performance—it’s about climate resilience, regulatory compliance, and sustainable growth. Synresins combines local knowledge, world-class technology, and eco-friendly innovation to help businesses thrive.

Whether you are in construction, textiles, packaging, or leather finishing, the right resin choice will define your durability and competitiveness in this fast-growing region.