Blog Page

Alkyd Resins: Benefits, Applications, and Why They Remain a Coatings Industry Essential

Introduction

What Are Alkyd Resins?

Alkyd resins are polyester resins modified with fatty acids or oils. The oil length—short, medium, or long—affects the resin’s drying speed, hardness, and flexibility:

- Short oil alkyds: Quick drying, hard finish, ideal for industrial and metal coatings.

- Medium oil alkyds: Balanced flexibility and cure time, used in general-purpose coatings.

- Long oil alkyds: High flexibility and weather resistance, perfect for decorative paints.

Key Benefits of Alkyd Resins

- Excellent Adhesion – Strong bonding to multiple substrates, including metal, wood, and masonry.

- Gloss Retention – Maintains surface appearance over time.

- Weather Resistance – Suitable for both indoor and outdoor applications.

- Versatility – Works in primers, enamels, varnishes, and speciality coatings.

- Cost Efficiency – Delivers high performance without inflating production costs.

These properties make alkyds an adaptable choice for a variety of market needs.

Applications in the Paint and Coatings Industry

Alkyd resins are used across sectors:

- Decorative paints – Interior and exterior wall paints that require smooth finishes and durability.

- Industrial coatings – Machinery, metal structures, and tools where abrasion and chemical resistance are important.

- Primers and undercoats – To improve adhesion and protect the underlying substrate.

- Wood finishes – Enhance the natural beauty of timber while providing a protective layer.

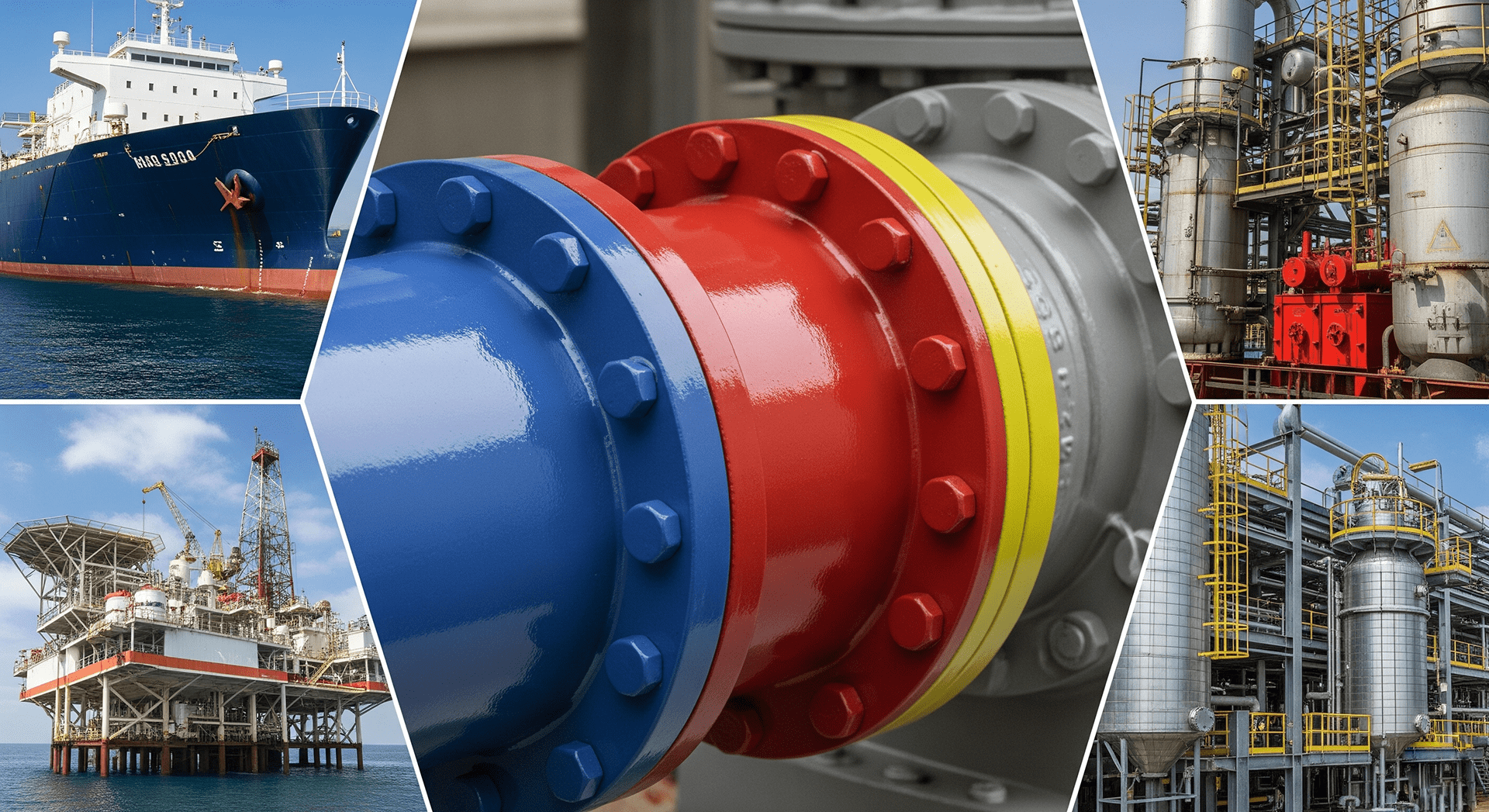

For example, alkyd-based enamel paints are widely used in protective marine coatings, where durability against water and salt exposure is critical.

Why Synresins Alkyd Resins Stand Out

Our alkyd resins are formulated and manufactured in Kenya, giving us a deep understanding of local climate and application challenges. Advantages of choosing Synresins include:

- Custom formulations developed through close collaboration with clients.

- Consistent quality backed by strict in-house R&D and quality control.

- Efficient production through Lean Manufacturing and Kaizen practices, ensuring 90%+ on-time, error-free delivery.

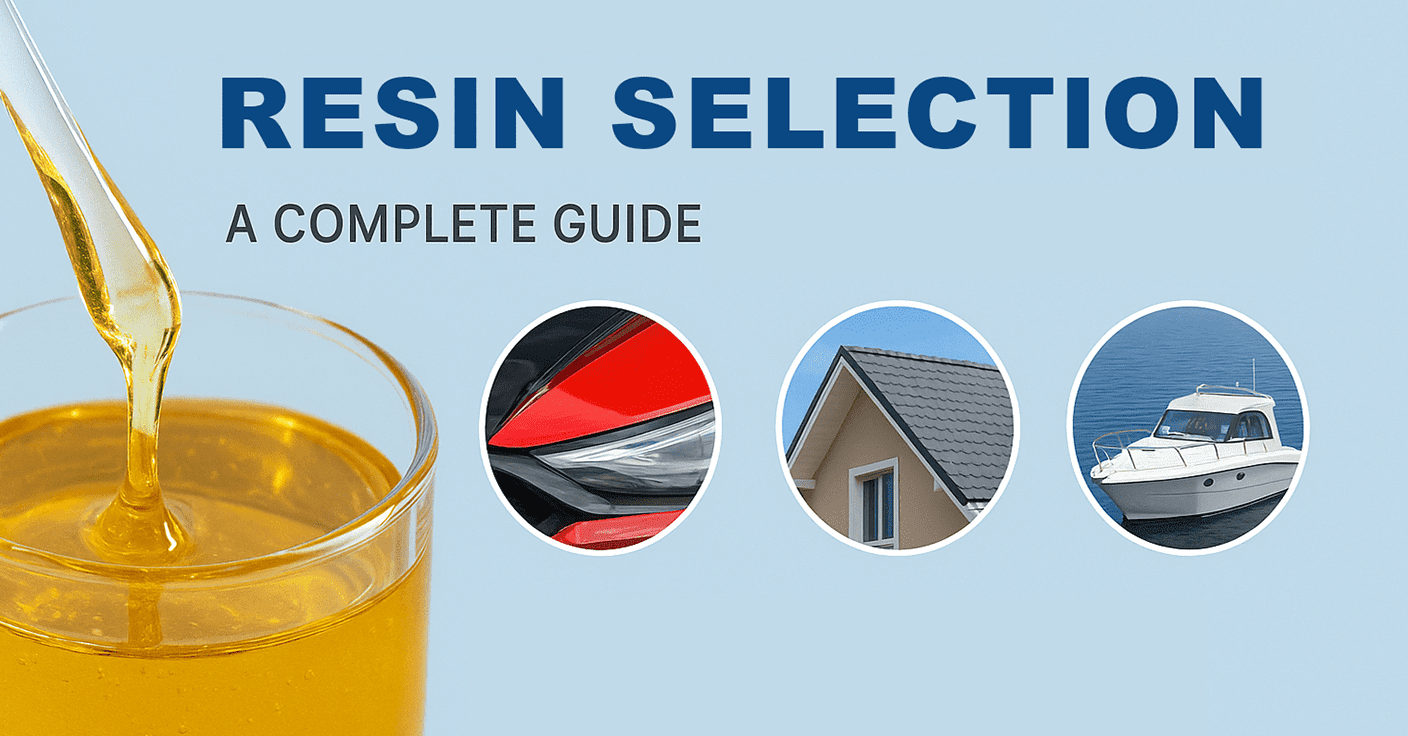

Choosing the Right Alkyd Resin

Selecting the right alkyd resin depends on factors such as:

- End-use environment (indoor vs. outdoor).

- Required drying time.

- Desired finish (gloss, semi-gloss, matte).

- Substrate type.

Our technical team can help you match resin specifications to your formulation requirements, improving product performance and production efficiency. See our full product range for details.

Sustainability and Future Outlook

Synresins is committed to developing eco-friendly resin solutions, including water-based alkyd emulsions, to meet evolving environmental regulations and customer expectations. These innovations reduce volatile organic compound (VOC) emissions while maintaining performance.

Conclusion

Alkyd resins remain an indispensable part of modern coatings technology. Their versatility, proven performance, and cost-effectiveness make them ideal for manufacturers looking to balance quality with value. By partnering with Synresins, you gain access to reliable, locally-produced alkyds backed by technical expertise and decades of industry experience.