Blog Page

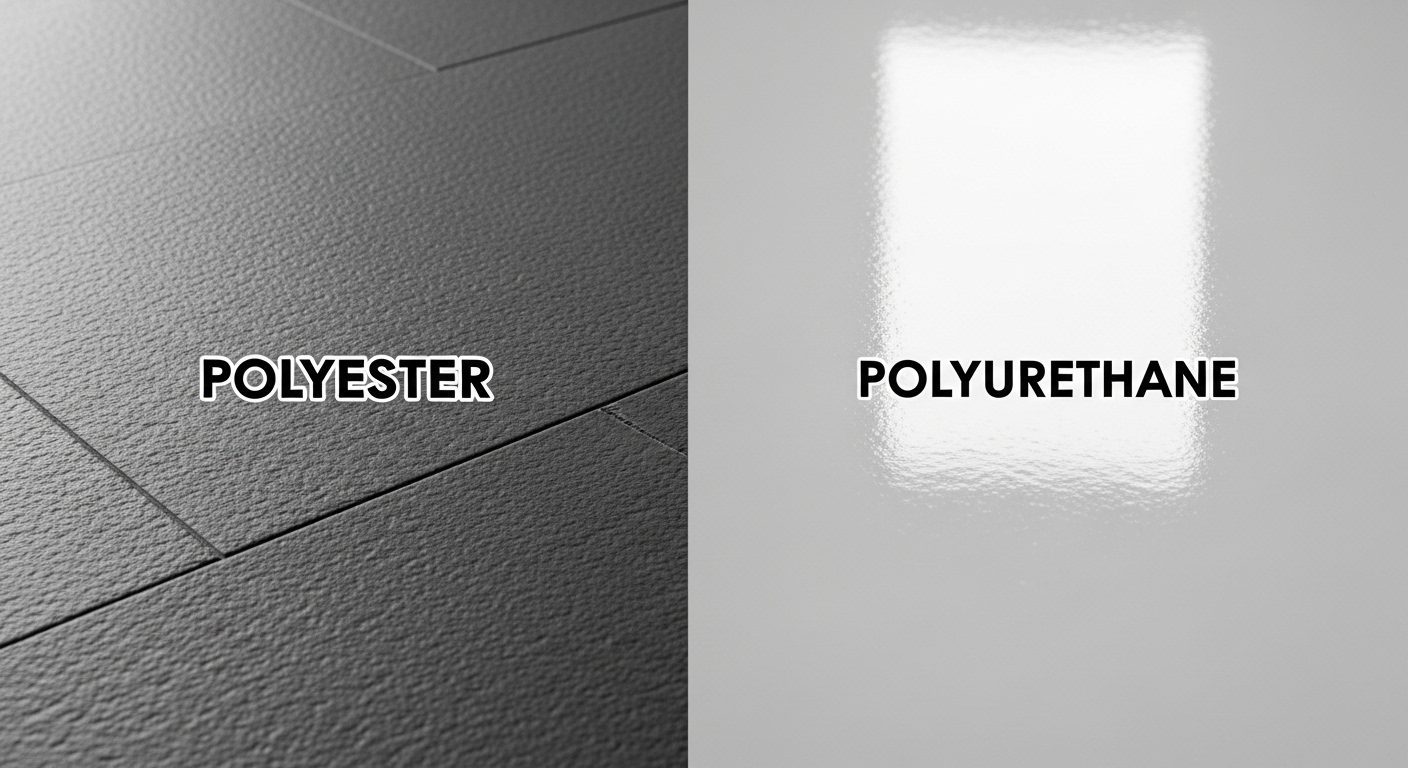

Polyester vs. Polyurethane Flooring in Kenya: Which Is Best for Your Facility?

Introduction

Choosing the right industrial flooring—polyester or polyurethane (PU)—can significantly affect your facility’s safety, durability, and operational efficiency. Whether you manage a food plant, warehouse, or cold storage, this guide will help you compare both flooring types to make an informed decision.

Polyester Flooring: Pros & Cons

Pros:

- High chemical & abrasion resistance – Ideal for food processing, pharmaceuticals, and heavy industry.

- Fast curing – Minimises downtime with a quick return to service.

- Cost-effective & low maintenance – Offers a long lifespan with minimal upkeep.

- FDA/USDA compliant – Suitable for hygienic environments like dairy and meat processing plants.

Cons:

- Less flexible – Not ideal for high-movement areas or fluctuating temperature conditions.

- Strong odour during installation – Requires professional ventilation.

Best for: Food factories, chemical processing zones, and high-traffic industrial areas.

Polyurethane Flooring: Pros & Cons

Pros:

- Superior flexibility – Resists cracking in freezing chambers and outdoor areas.

- Excellent UV resistance – Prevents yellowing in sunlight-exposed zones.

- Slip-resistant & ergonomic – Comfortable for workers standing long hours.

- Wide chemical resistance – Handles exposure to oils, solvents, and hot water.

Cons:

- Moisture-sensitive installation – Requires strict environmental control.

- Higher upfront cost – More expensive than polyester initially.

Best for: Cold storage, multi-storey car parks, laboratories, and sports facilities.

Quick Comparison Table

| Feature | Polyester Flooring | Polyurethane Flooring |

|---|---|---|

| Chemical Resistance | High (acids, caustics) | Excellent (oils, solvents, hot water) |

| Flexibility | Rigid | Highly elastic |

| UV Stability | Good (with blends) | Excellent (aliphatic PU) |

| Installation Complexity | Fast cure, strong odour | Moisture-sensitive, longer cure time |

| Cost | More affordable | Higher initial cost |

Anti-Slip Flooring Solutions in Kenya

Both polyester and polyurethane can be enhanced with anti-slip aggregates like #16 silica sand or aluminium oxide. These are ideal for:

- Food processing plants

- Warehouses & logistics centres

- Commercial kitchens

- Outdoor & wet-prone areas

How to Choose the Right Flooring

Before deciding, assess your facility’s unique conditions:

- Traffic load: Foot traffic, forklifts, vehicles

- Chemical exposure: Acids, oils, cleaning agents

- Temperature fluctuations: Freezers, hot washdowns, UV exposure

- Budget vs. lifecycle cost: Upfront price vs. long-term maintenance

Need Expert Advice?

Book a Free Site Assessment with Synresins Kenya for tailored flooring solutions built to withstand your operational demands.

Why Choose Synresins Kenya?

- Local expertise in industrial resin flooring

- Custom anti-slip coatings for safety compliance

- End-to-end installation and support

Get started today!

Contact Us |

Follow us on Facebook

1 comment on “Polyester vs. Polyurethane Flooring in Kenya: Which Is Best for Your Facility?”

Ibrahim

Great.